QES has a client base drawn nationally from a diverse range of industry sectors incorporating major blue chip organisations as well as various small and medium sized companies. This variety enables us to continually build upon our experise, flexibility and understanding of different methods of manufacture.

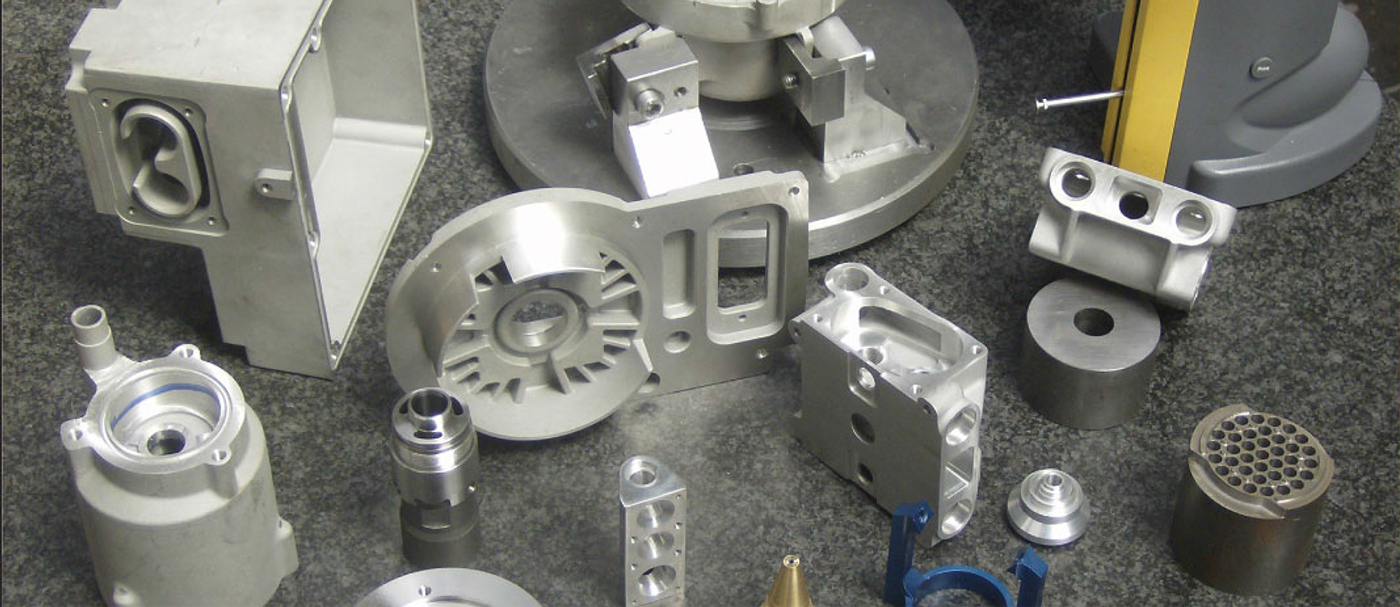

We have machined components in various materials from stock bar, castings and forgings in small batches up to 50-off but can accomadate larger batch sizes.

Surface treatment processes can be undertake with ease due to our central location and the abundance of services offered by local businesses.

Typical surface requirements have been heat treatment, anodising, copper plating, hard chrome plating ect.

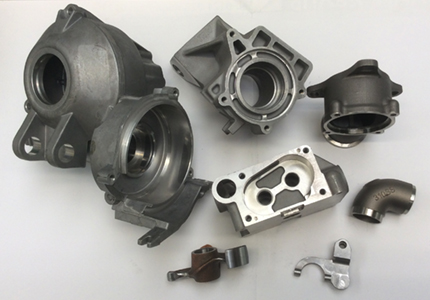

Components manufactured mainly from aluminimum alloys, plastics or stainless steels.

One of the items shown have been anodised and screen printed to customer specification.

The main materials we machine are aluminimum alloys, copper,stainless steels and plastics which are usually supplied free issue.

Close tolerances and surface finishes are achieved with our modern machines and quality control is checked with our calibrated inspection equipment.

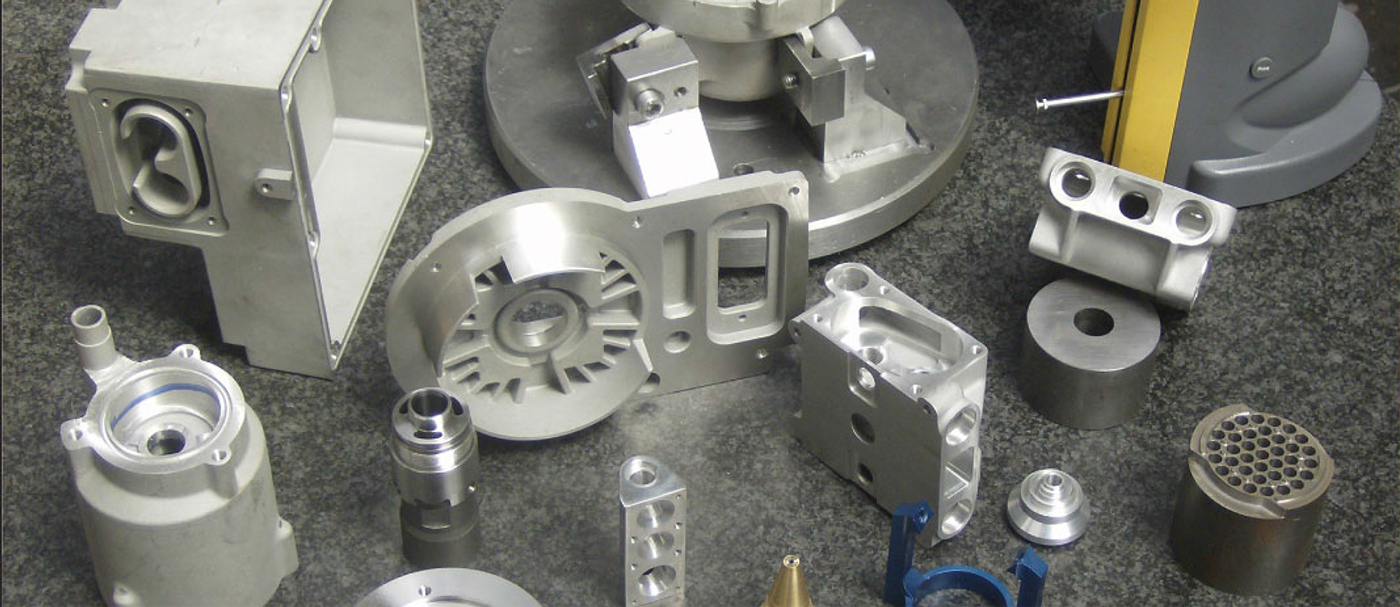

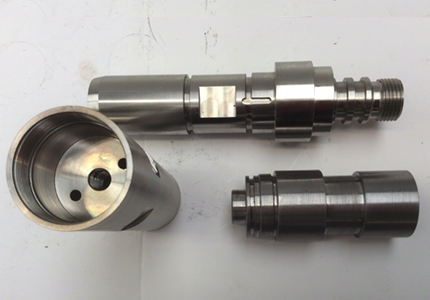

Components machined from bar or investment castings. Materials usually machined are stainless steel, inconels and duplex.

Our most chalenging material to date was Stellite 6 in cast form with intermitting cutting.

Components manufactured from stainless steel bar or investment castings, typical batch size ranging from 20 - 500-off

Threads and sealing faces are very important and so 100% inspected at machining operation.

Material used is fully certified

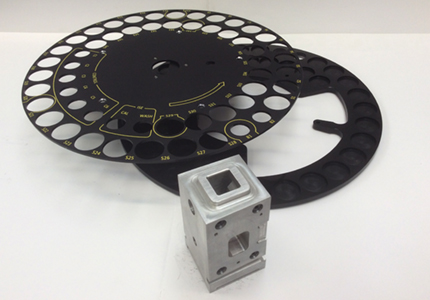

The exhibition work covers most steels, stainless steels, plastics and is very diverse from small bespoke fixings to elaborate components requiring 4/5 axis machining.

Generally the main consideration is asthetics rather than fine tolerances.

QES is capable of taking a customers idea to prototype stage and then production.

We can generate CAD models and drawings prior to manufacture of a prototype which can be used for function testing, evaluation and CE testing ect.

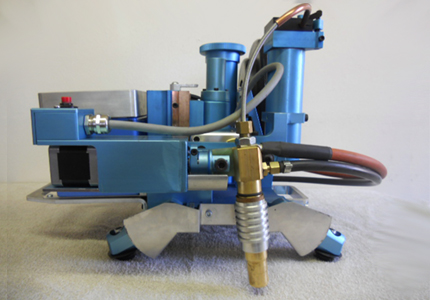

The picture shown is an automatic orbital welding machine used for pipeline construction.

All components were designed and manufactured at QES and include most materials generally avaliable.

We have machined other components from numerous companies from many different industries from CNC machine manufactures to the companies in the gaming industry.